Testing to assure the quality:

Mechanical Testing:

In this testing, our professionals evaluate the cables' tensile strength, elongation, impact, crush resistance, and other properties. We ensure the cables meet an application's requirements, and their mechanical qualities are tested.

Electrical Testing:

Testing is done on the cables to check for shorts, faulty wiring, and open wires through a couple of wires. Connecting the connector assembly to an electrical fixture with a mating connector ensures the circuitry works as per design.

Signal Integrity Testing:

For their effectiveness in maintaining signals in the particular application, signal integrity analysis is done. Common test types include crosstalk, error testing, and transmission power testing.

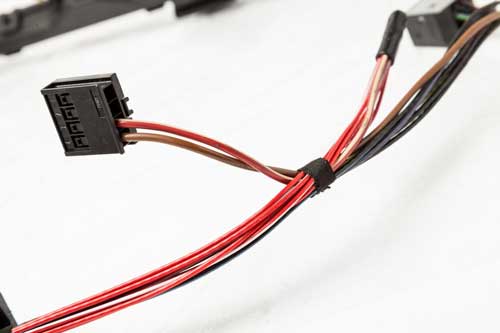

Visual Testing:

The wires and cables are visually inspected by our skilled test engineers for signs of damage, which can happen at any point during the manufacturing process. To make sure the connection is solid and electrically safe, they also evaluate connectors, sockets, and enclosures. Verify that the assemblies adhere to the requirements of the applications, etc.

Environmental Testing:

Cable and wire harness assemblies are used in various applications, indoors and outdoors. We determine whether the cables and wire harness are appropriate for the design's specified application. Conditions like high temperatures, salt fog, seawater spray, moisture, and other factors may be present while the assembly is used.