Custom Moulds Manufacturing Services

Quality Moulds for Enhanced Production Efficiency

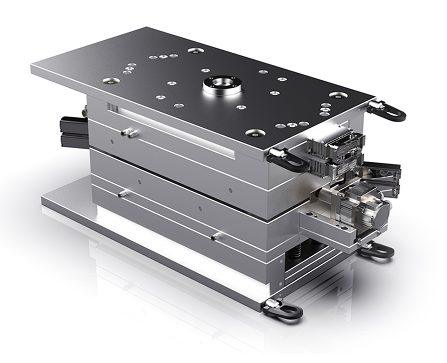

At Mefron, we specialize in crafting high-quality injection moulds that prioritize precision and efficiency. Serving diverse industries such as electrical and electronics, automotive, and healthcare, we offer everything from simple single-cavity moulds to intricate multi-cavity designs. Our premium mould bases and carefully selected tool steels ensure durability and long-term performance.

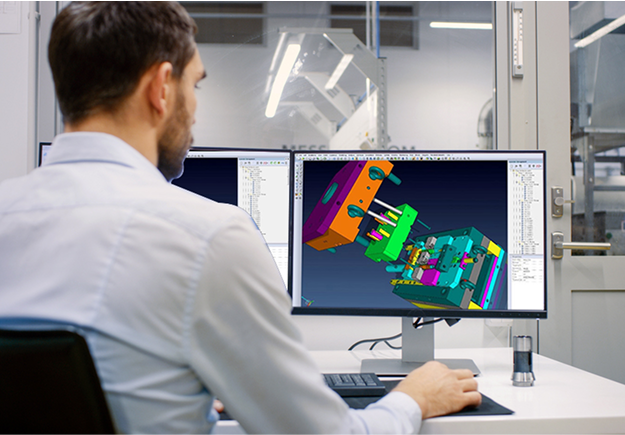

With an in-house team of engineers, we develop bespoke designs tailored to your specific needs, utilizing state-of-the-art 3D-CAD/CAM systems for precise layout creation. Our advanced manufacturing capabilities include CNC Lathe Machines, VMC Machines, EDM Wire Cut and Drill, Spark EDM Machines, and Cylindrical Grinding. This robust infrastructure enables us to maintain end-to-end control over the mould-making process, guaranteeing quality and efficiency.