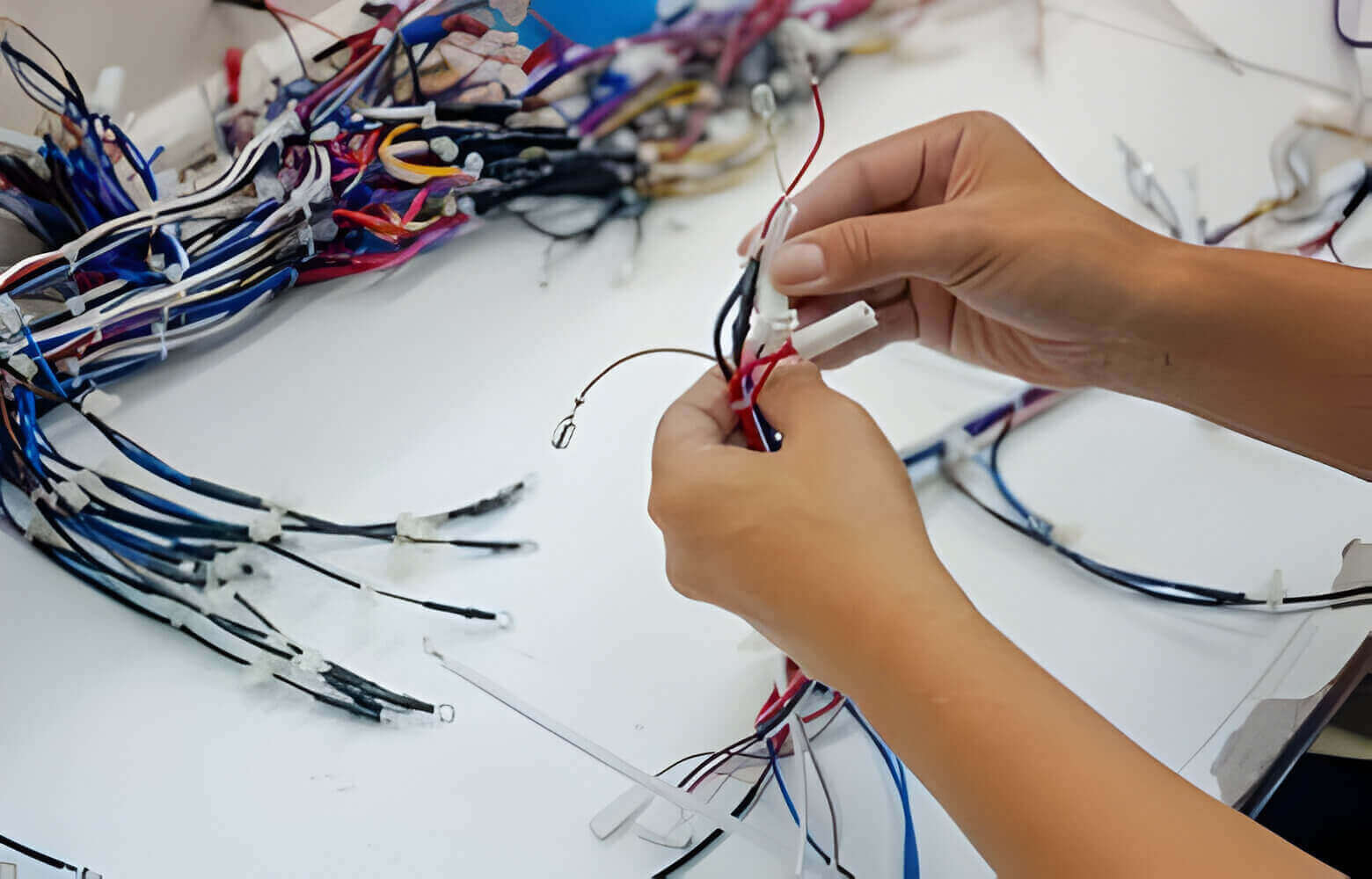

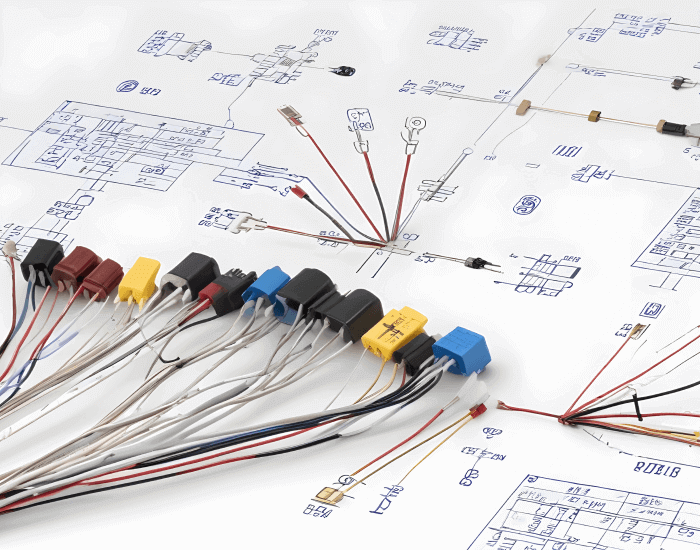

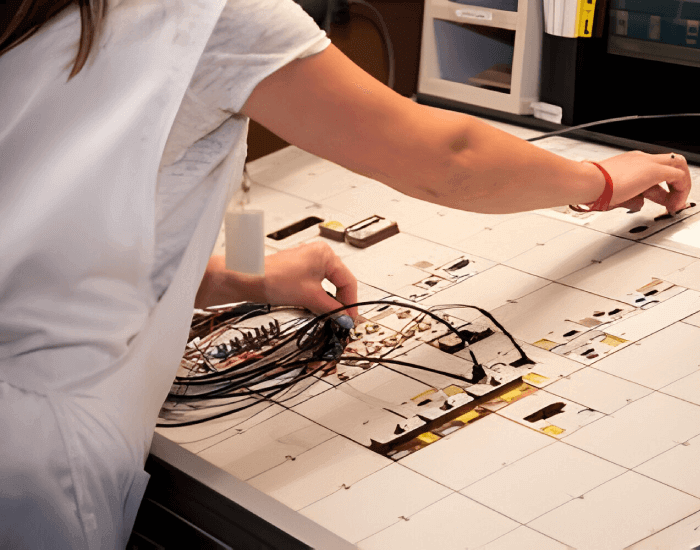

Custom Craftsmanship : Cable and Wire Harness Assembies For Your Unique Needs

Mefron delivers custom cable and wire harness solutions that power your success. From complex designs to launch-ready prototypes, we bring your ideas to life with precision and reliability.Our experts become an extension of your team, guiding you from vision to a perfectly crafted custom cable and wire harness solution. No matter the complexity, we work directly from your designs, ensuring optimal performance with expert advice on materials, production, and cutting-edge CAD design.