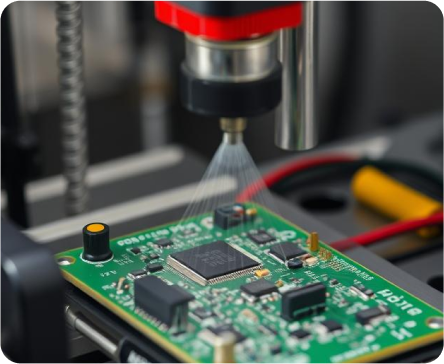

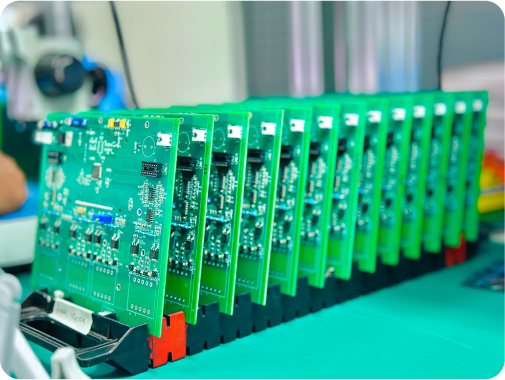

End-to-End PCB Assembly Services

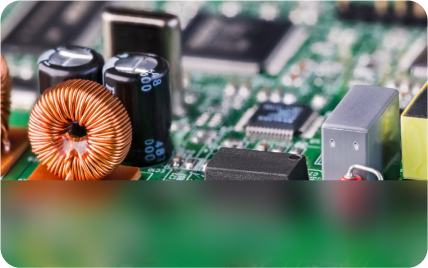

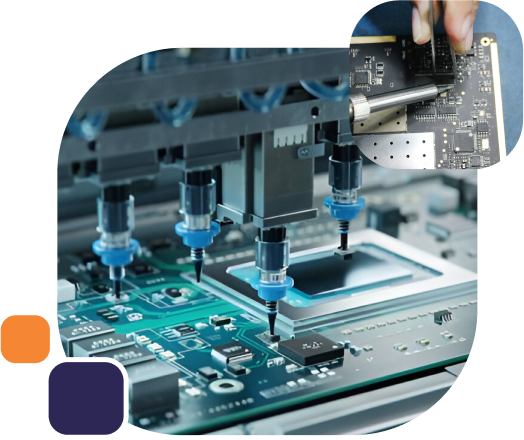

At Mefron, we provide reliable and precise PCB assembly services, including SMT and through-hole PCB assembly, for a variety of industries. With years of expertise and state-of-the-art technology, we ensure that every assembled PCB meets the highest quality standards. Our capabilities span from HMLV (High-Mix Low-Volume) to LMHV (Low-Mix High-Volume) PCB assembly, designed for efficiency and accuracy.

Our robust infrastructure and thorough testing processes make us a trusted partner in PCB assembly. We prioritize quality through meticulous inspections and advanced machinery, ensuring zero defects. Partner with us for exceptional service, quick turnaround, and cost-effective solutions tailored to your needs.

Capabilities Overview

Quick Insight into Our Capabilities and Expertise.

PCB Size

Minimum Board Dimension: 50mm X 50mm

Maximum Board Dimension: 508mm X 400mm

SMT Component Size

0201 to 74mm X 74mm and 32 x 180mm

Component Height - 25mm

BGA Pitch - 0.25mm

150,000 CPH

Order Options

High-Mix Low-Volume

Low-Mix High-Volume

Low Volume for Prototyping

Conformal Coating

Acrylic Conformal

Parylene Coating